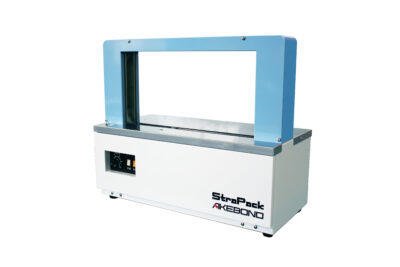

Professional Banding Machines for High-Volume Packaging Operations

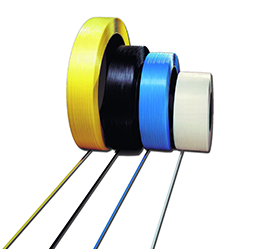

Discover our comprehensive range of industrial banding machines designed for efficient packaging across food & beverage, manufacturing, and distribution industries. From high-speed automatic models to compact workspace solutions, our banding equipment ensures secure bundle packaging with paper or film tape. Trusted by manufacturers for over 40 years, John Maye Company delivers reliable equipment with 24-hour fulfillment and expert technical support.