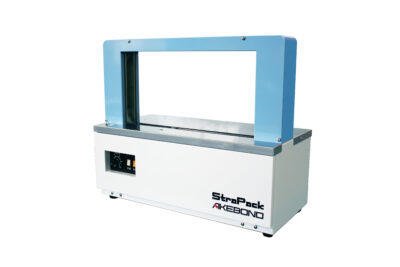

Premium Strapping Machines for Secure Industrial Packaging

Discover our comprehensive range of automated and manual strapping machines designed for high-volume packaging operations. From tabletop units to portable pallet strappers, our equipment ensures reliable, efficient securing of products across industries including food & beverage, manufacturing, agriculture, and logistics. Built for durability and precision with advanced DC motor technology and customizable configurations.