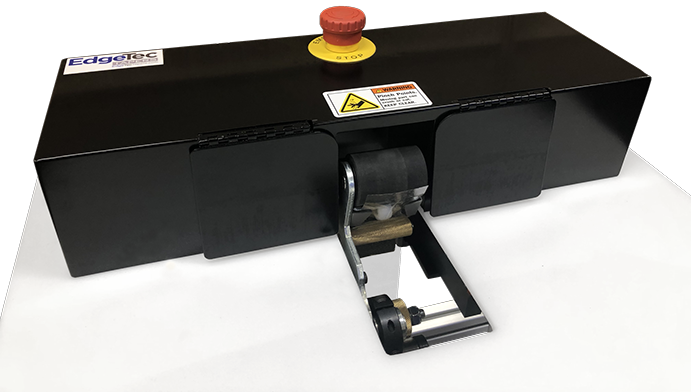

L-Clip Series Machine Specifications

Complete technical specifications for EdgeTec L-Clip 100, 200, and 300 series semi-automated case sealers designed for industrial packaging operations.

Why Choose EdgeTec L-Clip Series

Experience superior performance with our US-made semi-automated case sealers, designed specifically for industrial packaging operations where consistent, secure corner closures are essential.

Versatile Box Compatibility

Seals five-panel folders, full overlap, telescoping, tuck fold, roll end tuck top, and custom boxes with consistent quality.

High-Speed Operation

Apply up to 35 L-clips per minute with intuitive bump-style operation for maximum productivity in your packaging line.

No Setup Required

Plug and tape operation with electric pneumatic sensors that prevent tape jams and ensure consistent application.

Zero Tape Waste

Precise application system ensures no tape waste while creating consistent, secure corner closures every time.

Customizable Configuration

Available with multiple tape heads, custom spacing, and various optional features to match your specific packaging needs.

US Made Quality

Engineered with durable materials for continuous industrial use, proudly manufactured in Saint Paul, Minnesota with superior quality control.

Your Questions About EdgeTec L-Clip Series

What types of boxes can the L-Clip seal?

L-Clip machines can seal five-panel folders, full overlap, telescoping, tuck fold, roll end tuck top, and custom boxes. Minimum box width is 3.25" (4.25" for L-Clip 300) and minimum height is 2.5".

Can I have multiple tape heads on one machine?

Yes, all L-Clips can be configured with multiple tape heads. Multi-head units have standard 10.5" spacing, customizable down to 8.75" (9.75" for L-Clip 300) with no upper limit.

What are the power and air requirements?

L-Clip machines require 85 PSI clean compressed air and either 110 VAC or 220 VAC, 50/60Hz, 1 Phase Power. All-electric options are also available.

What optional features are available?

Options include box guides with flap closers, low profile taping, safety guarding, ball tables, washdown machines, inline air filters, lag legs, variable tape legs, and all-electric operation.

Get Automation Updates & Resources

Stay informed about new packaging automation technologies, application guides, and product updates directly from our automation experts.