Complete Technical Overview

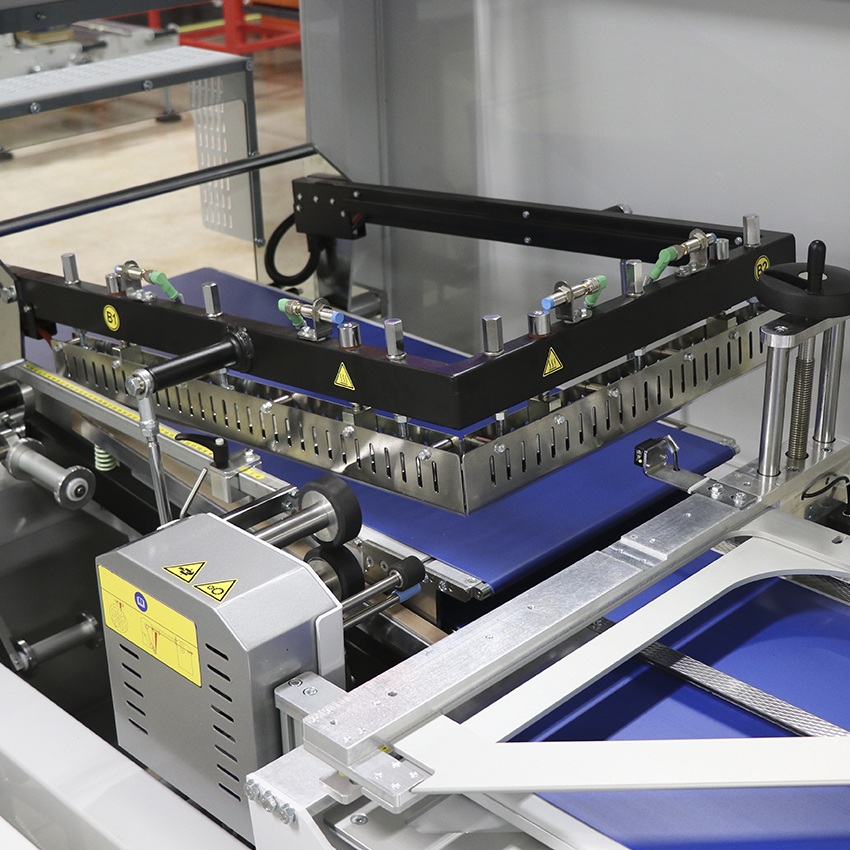

Detailed technical specifications for our professional-grade FP560A semi-automatic L-sealer systems, featuring full electric operation with precision sealing.

Why Choose the FP560A?

Experience superior packaging performance with professional-grade L-sealers that deliver exceptional quality-to-price ratio for even the most demanding production requirements.

Exceptional Value Proposition

Outstanding quality-to-price ratio makes professional L-sealing accessible to businesses while maintaining industrial-grade performance standards significantly.

Complete Modular Flexibility

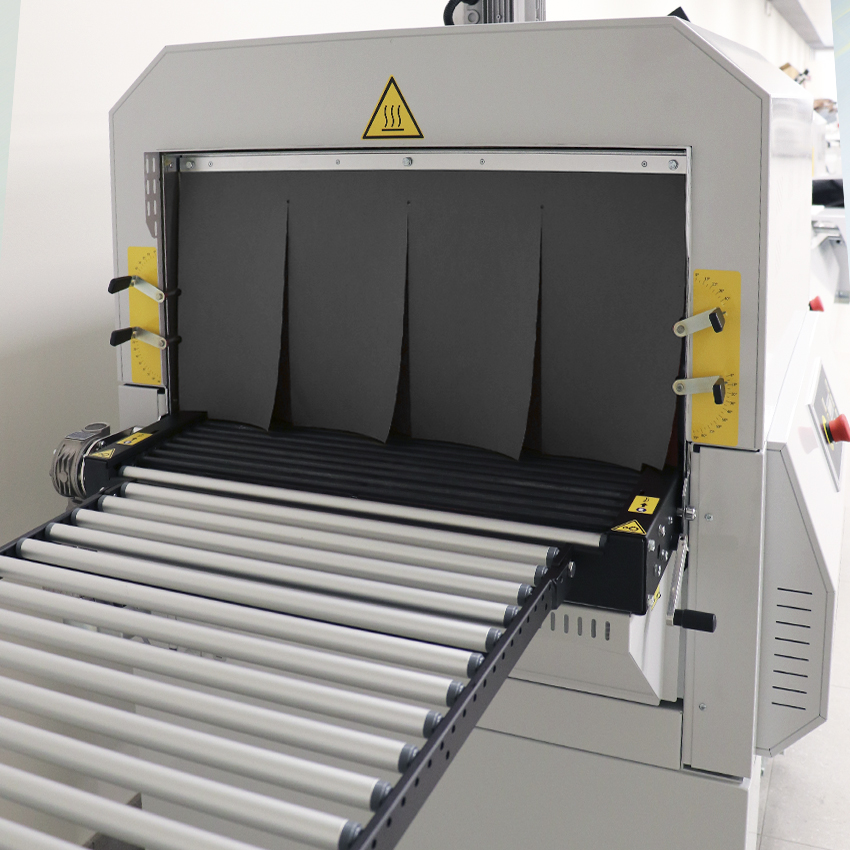

Designed with adaptability, the FP560A can be supplied with or without shrink tunnels, allowing customization for exact requirements.

Food Industry Ready

Available INOX version features AISI 304 stainless steel with FDA compliant conveyor belts, ensuring complete food safety compliance.

Advanced Film Compatibility

Unlike traditional L-sealers limited to shrink films, handles PVC, Polyolefins, and Polyethylene, providing unprecedented packaging versatility requirements.

Superior Output Performance

Engineered for efficiency, achieves higher output rates than conventional L-sealers, with capacity up to 1,500 packages per hour enhanced.

Universal Industry Application

From bakery to electronics, serves multiple sectors including pharmaceutical, automotive, and consumer goods with reliable, consistent results.

Common Questions Answered

Is the FP560A suitable for food packaging applications?

Yes, the INOX version features AISI 304 stainless steel construction with FDA/UE/USDA compliant belts, ideal for direct food contact applications.

What's the actual output capacity I can expect?

The FP560A can achieve up to 1,500 packages per hour, though actual output depends on specific product size, packaging configuration, and film type.

Can I add shrink tunnel later if not initially purchased?

Absolutely. The FP560A's modular design allows standalone L-sealer operation and add compatible shrink tunnel whenever production needs expand significantly.

What industries commonly use the FP560A system?

The FP560A serves diverse sectors including food industry, consumer goods, industrial applications, and specialty markets with pharmaceutical printing optimal performance.

Get Technical Resources & Updates

Stay informed about new L-sealing technologies, installation guides, and maintenance tips directly from our professional engineering team.

Documentation & Support

Access comprehensive technical documentation, installation guides, and compatible accessories for your FP560A semi-automatic L-sealer system configuration.